In today’s competitive electronics industry, hardware designers are often hard-pressed with shorter product development time and complicated electronics design. Yet, prototyping is still a significant process to make sure every aspect of the design is functional before launching into the market. In this post, we’re looking at different stages of electronic prototyping in China and how to leverage them more effectively to launch your products into the market in the quickest time.

Table of Contents

Different Types of Electronic Prototyping in China

Proof of Concept (POC) Prototype

As the name suggests, the proof-of-concept prototype is a roughly put-up prototype to check whether the idea is feasible or not. A POC prototype is usually developed to validate key points in the design. For instance, you’re planning to build a wireless humidity sensing data logger, and you want to validate whether the storing function can be accomplished with a flash chip. You come up with a POC prototype integrated with various types of wireless test modules, allowing you to evaluate and choose the best solutions. A POC prototype serves as a reference to minimize cost and save time when the feasibility of a design idea.

Is POC Prototype Necessary?

It’s not necessary if you’re working on designs with features that you and your team are sure of their functionality. However, it’s best to have it if you must explain the idea to an external partner who is not sure about the features.

Looks-Like Prototype

Designing an electronic product isn’t merely about the design of PCB and components. The electronic enclosure is essentially important for a product to be able to launch into the market. Consumers or backers would want to know what the final product looks like prior to its debut on the market. That’s where a looks-like prototype steps in to help.

A looks-like prototype provides the visual appearance, style, and mechanical structure of the final product. It usually serves as a visual guide of what the final design looks like. In addition, the PCB should be aligned to the mechanical fittings and fits well into the enclosure.

Presenting a looks-like prototype helps in pitching an idea to potential investors for funding purposes. It’s easier to show a product with an easily comprehensible prototype to non-technical individuals than with a complex multilayer PCB.

Building a looks-like prototype used to be costly in the past but not so with the development of technology like 3D printing. There is a variety of wallet-friendly approaches commonly used in building these prototypes.

3D Printing

The prevalence of 3D printing technology has made electronics prototyping much faster and cost-effective than before. 3D printing allows hardware designers to build prototypes within hours using materials like PLA, ABS, nylon, carbon fiber, wood, metallic, etc, depending on the type of 3D printer you use. Once the 3D printer is set up with the CAD drawings, it starts to deposit layers of materials based on the CAD drawings.

CNC

Computer numerical control, also known as CNC, is a commonly used prototyping process before the prevalence of 3D printing technology. It involves removing or carving parts of a block of material based on the engineering drawings. CNC machines work well with an extensive range of materials such as plastic, wood, glass, foam, etc., as long as the design is not extremely complex.

Works-Like Prototype

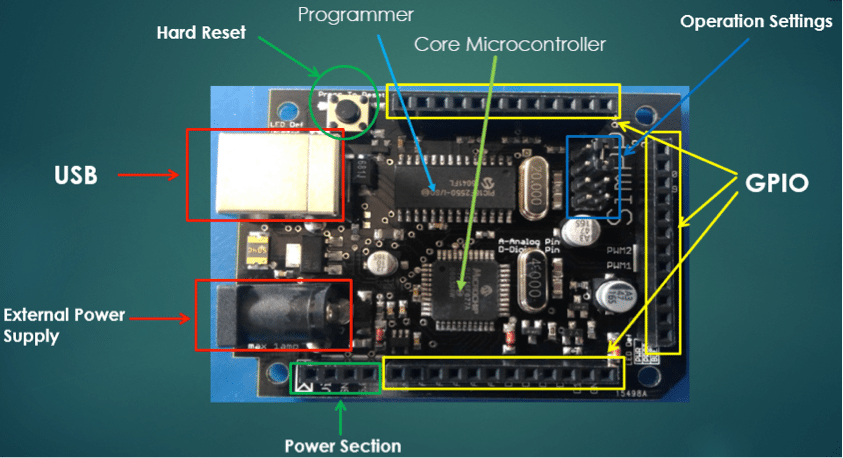

Different from a proof-of-concept prototype, a works-like prototype is used to demonstrate the product’s functionality, which is a decisive factor for the success of any electronic product. Therefore, a works-like prototype is an essential part of the product development process. Hardware engineers have to design a prototype that features all the necessary functionalities as specified in the product specifications.

Developing a works-like prototype also takes reliability and robustness into account. For example, the circuit needs to be functional even in excessive heat or humid circumstances. To build a works-like prototype, the hardware designers usually have to build the PCB layout from scratch. The dimensions of the PCB as well as the mounting holes should be tailored to the actual requirements.

Building a works-like prototype is an iterative process that you might encounter problems on the first attempt. It’s critical to jot down the electronic design mistakes and rectify them. It would take a few revisions before you get an ideal works-like prototype.

Engineering Prototype

Once you get a works-like prototype and a looks-like prototype, it’s time to assemble them, and the result is an engineering prototype featuring both visual appearance and functionality. An engineering prototype is essential for field testing as it has all the features of a possible final product.

Pre-Production Prototype

An engineering prototype might be field-tested and proven to be reliable, however, it isn’t good enough for mass production. You’ll need a pre-production prototype that is designed for manufacturing. The PCB layout and enclosure must be optimized with good DFM practices. Having a pre-production prototype with manufacturability in mind can lead to cost reduction and faster lead time.

Leave a Reply

You must be logged in to post a comment.