Power banks have become increasingly popular as the battery life of our phones is outstripped by the amount of time we spend using them each day. Portable and fashionable, these gadgets have become a necessity for outings.

Shenzhen, home to China electronics manufacturing, proudly boasts hundreds of power bank manufacturers. Yesterday we made a visit to a power-bank factory in Shenzhen – Maoxin power bank factory.

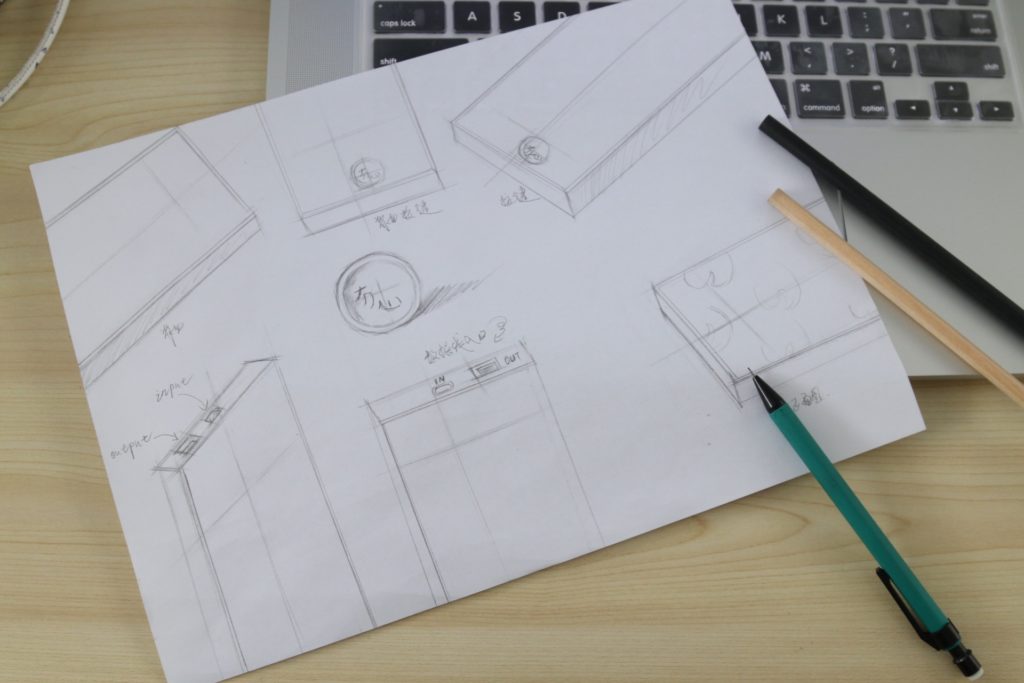

Design is of vital importance at the initial stage of manufacturing power banks. From the design team in Hangzhou to the ones in Hongkong and Shenzhen, Maoxin spares no effort to make the power banks more appealing and user-friendly.

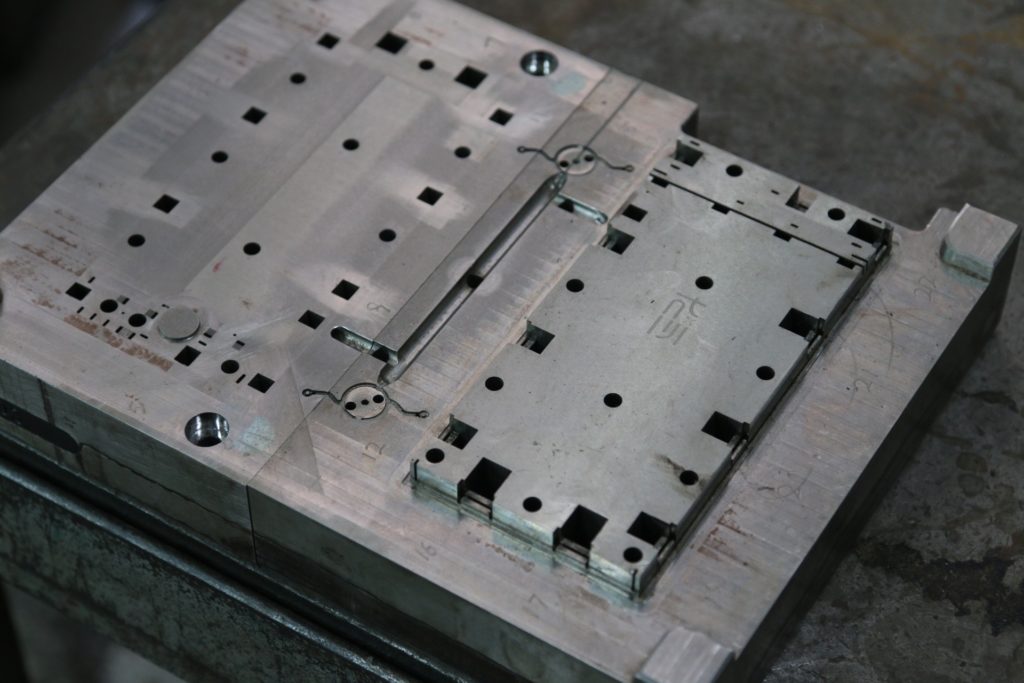

Next comes to the mould of power bank. Accuracy and attention to detail in crafting the moulds play a decisive role whether the power banks can stand out as high-end products or merely cheap knockoffs.

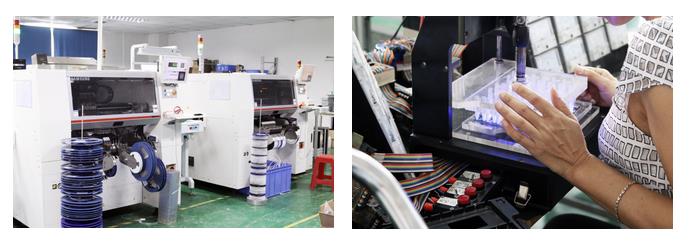

An important element of a great power bank lies in the PCBA motherboard with a special circuit to control power flow. As you might read from the news some cheap power banks can not charge, or getting too hot after charging for few hours, or even explode, all these are related to PCBA mother board. A high quality PCBA motherboard can ensure the security of power flow and avoid problems such as getting burnt out, explode, etc.

Battery is the vital most important part of a power bank. Normally there’re two kinds of batteries: Li-polyme battery and li-ion battery. The latter one with slight body and minimum capacity of 8,000Mah is usually used in manufacturing power banks.

Water transfer printing is widely applied in manufacturing cases for power banks. In about 2-3 days when the cases get dried after water transfer printing, they will be put into dust-free spraying room to apply a layer of rubber oil. After 45 minutes’ of high temperature baking, different parts of the power banks are almost ready.

Now it’s time to assemble different parts together and carry out quality inspection.

A layer of tape is sticked to the battery to avoid leaking of fluids and swaying inside the case.

Next, PCBA motherboard and battery are soldering together.

Then it will take about 1-2 days for the assembled parts to go through aging tests.

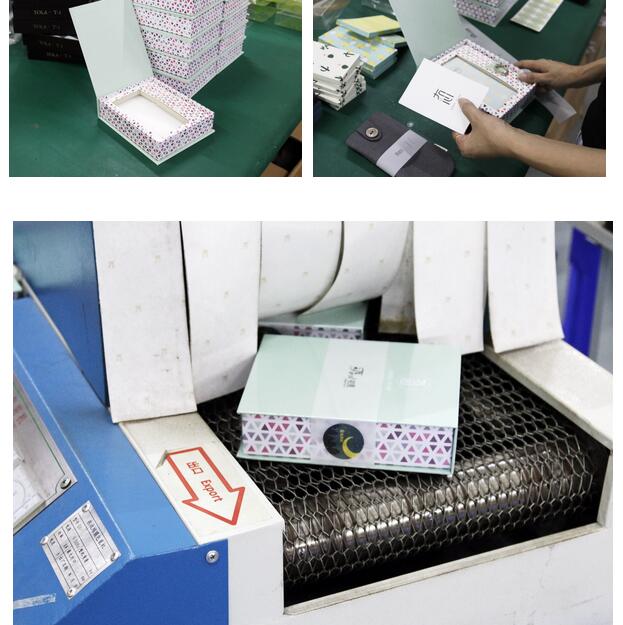

After carefully selecting the qualified parts, it’s time to assemble all the components and pack them together.

CHINA HAS A LOT TO OFFER TO THE WORLD. OTHER COUNTRIES SHOULD LEARN FROM THEM.

Thanks Asgar.

There are no direct access to contact the distributors