Thinking about adding an extra layer of security to your smart phone screen, the second most expensive part of a smart phone to replace? Good screen protectors are just as vulnerable to regular falls and drops, scratches and cracks. Applying a screen protector to most people’s daily essentials to stop them from potential scratches and other damages has been a popular practice for past few years.

The challenge for most people is to decide which screen protector is most suitable as there’s an intriguing spectrum of screen protectors online ranging from insanely priced at $0.5 plastic screen protectors to tempered glass ones that cost a bit level up.

In this post you’ll learn about how screen protectors are manufactured, and we’ll show you some pictures of our previous visit to a tempered glass screen protector factory in China.

Table of Contents

The China electronic manufacturer takes up a massive scale of over 15,000 square meters in the outskirt of Shenzhen. As tiny and thin as tempered glass protectors appear to be, it requires a comprehensive set of equipments to produce them from scratch. As we idle our way through the manufacturing facility, let alone the sheer scale, the diversity and total quantity of machines on site are really blowing us away.

List of Machines to Produce Glass Screen Protectors

1. Glass cutting machine

2. CNC machine

3. Polishing machine

4. Tempering machine

5. Ultrasonic cleaning machine

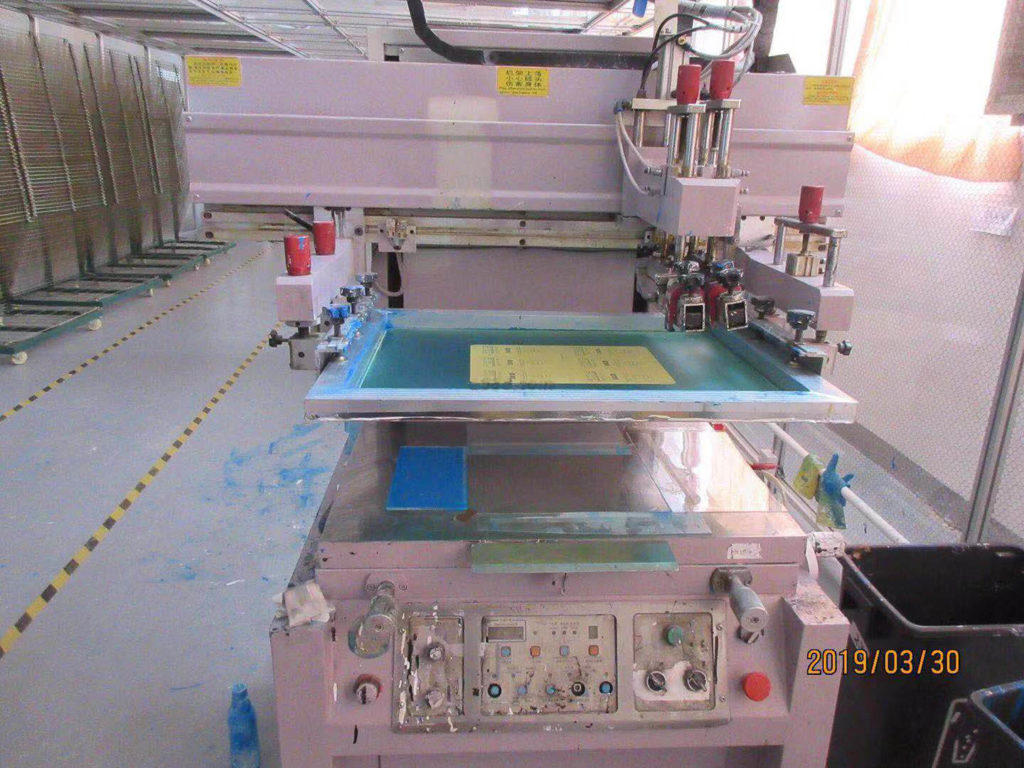

6. Screen printing machine

7. Glue laminating machine

8. Oil spraying machine

Procedures of Manufacturing Glass Screen Protectors

1. Rough Cutting

The selected raw materials sourced from downstream suppliers will be cut into pieces with specifications close to the size of mobile screen.

2. Precise Cutting

Then CNC machine comes into play. All the roughly cut pieces would go through another process of precise cutting. The shapes will be meticulously and precisely carved using CNC machine to fit the mobile screen perfectly. Besides, the holes will also be cut in the exact location.

3. Polishing

To get a more comfortable and smooth touch, glasses will be grounded and polished, and the four angle edges will be curved to round shape.

4. Tempering

The most vital step of the manufacturing process, and it’s also how ordinary glasses retain the resilience and hardness against regular scratches and cracks. After going through a process of heating up the glass to for a sheet and rapidly cooling it, the glass would reach a level of at least 4-5 times stronger than what it was before.

5. Ultrasonic Cleaning

After tempering, ultrasonic wave cleaning technology is applied to get rid f dusts, powders, fingerprints as well as other smudges from the glasses.

6. Screen Printing

This is how glass gain colors.

7. Glue Laminating

Usually AB glue would be laminated to the glass, helping it absorb fast and stay bubble free when installing the glass into mobile screen.

8. Oil Spraying

Later, anti-fingerprint oil will be sprayed on the glass.

9. Tests and Quality Inspection

All the glass will go through a stringent series of tests to make sure the quality reach required standard, i.e., anti-water, anti-fingerprint, anti-oil, anti-drops and falls. Besides, some tests are also carried out to make sure the hardness and light transmittance effects.

10. Packing

Which Should You Choose, Plastic Screen Protector or Tempered Glass Screen Protector?

Plastic film protectors have been dominating the consumer electronic market before the emerging of tempered glass counterparts, which quickly stole a bigger slice of the pie. There’re a few prominent differences that set them apart.

1. Price

Plastic film protectors often feature insanely low price tags while tempered glass tend to cost more. The price difference lies in the quality of raw materials and technologies applied to manufacturing them.

2. Installation

While applying to mobile screen, plastic film protector might roll up easily as it’s ultimately s sheet of plastic. Thus, you have to install them carefully.

3. Toughness

Compared with tempered glass, plastic protectors are not so helpful against falls and drops

4. Touch

Apart from better resistance against drops and scratches, tempered glass come with a better touch with close feel of your original screen. The difference is easy to notice when your finger glides.

5. Look

Due to the thickness, tempered glass protectors are, in particular, a bit bulged out than plastic protectors.

Check out guide about importing tempered glass screen protectors from China.

I need mobile protector in quantity can u plz guide me

HELLO MUHAMMAD ARSALAN I want to buy large quantity of screen protectors, can you help me to find direct factory and high quality products

jitendra69kumarraj@gmail.com