Prior to securing a big order, factories in China tend to promise they can produce the exact products you want paired with premium quality. The problem is, however, as lessons learned the hard way to a great number of importers, entrusting the salesperson with all the responsibilities of manufacturing, in most circumstances would lead to either poorly made products or failure in meeting delivery time. Then how to prevent all these problems while importing from China?

A significant number of importers tend to carry out factory inspection as an effective way to assess whether the manufacturing facility meets the standards or not, as well as an opportunity to strengthen relationship with the Chinese suppliers. Factory visits, to a great extent, can kick the quality up a notch, enhance communication and minimize production delays. Without a solid groundwork, you might be rushed through a brief tour without ample time to ask question, inspect carefully and might fail to identify potential issues. There’s no denying that planning factory visits can be overwhelming. Our seven tips with essential information to prepare for factory visit is dedicated to helping you make the most out of it.

7 Tips for Effective China Factory Visits

1. Manufacturing Organization

A poor factory organization poses lots of trade-offs, which can negatively affect cost, product quality, lead time, service, etc. A functional manufacturing organization involves three parts.

* An effective organization structure

* A pool of skillful and dedicated workforce

* A strong supporting and governing system

Here’re a couple of questions to consider when visiting a China manufacturing facility to evaluate its organization.

* How are engineering, assembly lines, maintenance, quality control, shipping, asset management and other functions integrated into the manufacturing organization?

* Are the manufacturing responsibility and decision making centralized or given to managers?

* What responsibilities do managers from different divisions have?

* Are raw materials, parts and semi-finished goods clearly labeled and neatly stocked in an accessible location?

2. Manufacturing Capacity

To convince you to place orders, some Chinese manufacturers tend to tell you a bigger manufacturing capacity and shorter lead time than what you require. Afterwards, the common practice is to outsource part of the production to sub-suppliers. It’s vital to validate it while visiting China factory as outsourcing to sub-suppliers might potentially cause some problems.

* Misunderstanding concerning product specification, quality requirements, etc

* Delays in delivery time

A responsible factory has plans for inconsistent manufacturing disruptions, like preparing for raw material shortage and national holidays, recruiting more talents, etc, even when they outsource part of the production to sub-supplier, a comprehensive set of quality inspection measures would be carried out to ensure quality of the goods and delivery time.

As a rule of thumb, in a staggering number of Chinese factories, each day/week/month production target and current progress is updated on the boards of the manufacturing floor. Check the real production capacity and manage your orders. Leave extra manufacturing time as it’s never a good idea to rush production, which would lead to potential problems like compromising in quality.

3. Social Compliance

A social compliance audit, in particular, reveals your supplier’s working conditions and business ethnics. During short-time factory visit, usually buyers can only spot whether the workers are working in a clean, safe environment or any hazardous elements on site. Here’re a few areas we suggest you to check during China factory visits.

* Is fair trade practice adopted in the factory? Are the workers paid well?

* Are workers wearing protective gear in certain manufacturing process?

* Is the factory neatly maintained and properly ventilated?

* Do you see any safety hazards on site, i.e., poor lighting, polluted water and unlabeled chemicals?

4. Working Instructions

A straight forward work instruction sheet clearly outlining the processes for workers at different stations and assembly lines is extremely important in minimizing errors.

A standard work instruction sheet should be:

* Simple with visual examples or graphics to illustrate each step

* Highly visible and noticeable, usually posted at each work station

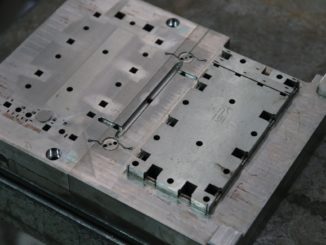

5. Equipment Maintenance

Investing in equipment maintenance is rarely considered as a necessity in a vast number of China factories, which, in bad circumstances, might contribute to non-conforming product specifications, disruption of productions, etc. Factory tours can help better understand which equipment are needed for your product manufacturing and which steps require manual labor.

Here’re some questions to ask during your next factory visits.

* Are the machines in good condition?

* Are the machines regularly inspected and maintained?

6. Warehousing

Next stage is to check the warehousing and storage of incoming raw materials and finished goods. Here’re a few factors to take into consideration.

* Scale of the warehouse

Are the incoming raw materials and finished goods neatly categorized and stored in different sections of the warehouse, or are they crammed up the entire warehouse?

* Storage conditions

Temperature, lighting, humidity and cleanness can have negative effect on raw materials, i.e., raw materials can degrade easily or making it hard to preserve quality of finished products.

* Receiving time of raw materials

For raw materials that are outsourced, they should be properly labeled with receiving dates.

7. Reviewing Samples

Overseas importers used to wait several weeks to receive the first sample. If the first sample doesn’t meet the specification, then another round of prototyping starts. It would take at least another few weeks for the factory to make another sample and ship again. Reviewing samples on site can let you give feedback directly, greatly speeding up the process.

Leave a Reply