So after months of working around the clock, you have finalized your product tech packs, created the first prototypes and it’s time for production. As you start to communicate with suppliers about manufacturing electronics in China, you get nerves on to share the Intellectual Property with factories that might turn out to be your biggest competitor. You’ve probably met with some lawyers about how to protect and patent your brand.

Though international trademarks do pose some enforcement power, it doesn’t necessarily mean people who steal your ideas would get heavy fines or put in jail immediately especially in China, it would suppose to be a long, hectic process with uncertain results. Nevertheless, there’re some helpful strategies to protect your intellectual property in the early stage of sharing your tech packs while manufacturing electronics in China.

Table of Contents

3 ways to protect IP while manufacturing electronics in China

* Divide your manufacturing to multiple factories

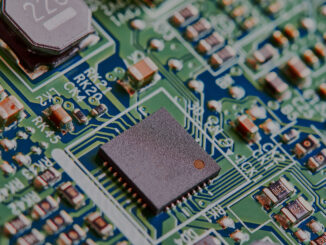

A powerful strategy to limit the number of people having access to the finished products is to compartmentalize your production. If your electronic gadgets consist of different components, you can have different factories producing different parts. For example, you can build the mold in one factory, PCB in another, housing in a third one then find an assembly company to kit all the parts together. Also referred to as black box manufacturers, some of these assembling companies offer service that ensures minimum number of people with access to your finished products and fewer people know where the components come from, how to put them together.

* Carry out factory audits

It’s essential to know well the factories you’re going to work with before committing to the deals. Though in my decades of experience with various Chinese electronics manufacturers, I’ve never seen any factory stealing the products of their clients and sell as theirs. However, factories are in a convenient position to run extra productions or incorporate the ideas into their other production lines if your products go well Have you ever reads the news concerning the Joyme Furniture with 90% of furniture identical to IKEA’s as many international media unveiled? It belongs to IKEA’s long established manufacturer for 16 years but split from IKEA due to the brand’s constant pushing for low prices. If you don’t want to end up like IKEA, precautions should be taken like adopting fair trade practices, establishing good relationships with the factory, etc. Here’re a couple of ways to access the factories you’re interested to work with and decide whether they’re a good fit for your electronics manufacturing in China.

1. Check if your factory sell B2C, whether they have a brand or not.

2. Test how much information your factory would give concerning their existing customers, ask about products belonging to those customers and see whether they’re willing to share or keep the information confidential.

* Find a third-party mold manufacturer and protect your mold

Mold is the essential part while it comes to manufacturing electronics in China. Sourcing a third-party facility to create the mold then ship to the next factory can prevent the factory having access to your 3D drawings and know about how it was made.

A tip to be aware of is always get your mold back or store it in a private space after one batch of production. What usually happens is after one batch of production the factory would just put your mold on a shelf next to other molds for next use. That would expose the mold possibly lead to leaking of ideas or unauthorized production.

Adding a small logo or other brand identifiers in discrete locations is also great way to determine if a counterfeiting mold is created. It would ensure your factory not using your mold for other clients’ orders.

Leave a Reply