If you’re thinking about electronics manufacturing in China, there’s a vital point to keep in mind. The tech pack of the product must be matured, otherwise, it might cause a lot of complications such as prototyping failure, unwanted goods, exorbitant costs to make up for a design mistake, etc. There’re several steps you should consider prior to engaging an electronics manufacturer in China for mass production.

Table of Contents

5 Critical Steps Prior to Electronics Manufacturing in China

Prior to kickstarting any electronics manufacturing project in China, you must make sure you’ve planned well for the following steps.

- Develop a product concept that involves thorough research of the target market, pricing as well as the supply chain system

- Work on the tech pack and makes sure it’s error-free, feasible, and functional

- Test functional prototypes to make sure whether it’s working or not

- Optimize the prototypes and plan for pre-production

- Start manufacturing in bulk

These are essential steps to mitigate risks if you’re launching a customized product. Don’t count on your Chinese manufacturer for everything from the product design to the product launch. A manufacturer is more specialized in producing the products from an existing, well-established design instead of working on the design themselves. They can help you with several pieces of prototypes or mass production, but you’re the one that is responsible to provide a working design and ensuring it’s matured without significant errors.

4 Mistakes to Avoid for Electronics Manufacturing in China

Before engaging to electronics manufacturing in China, it’s critical to review your product design thoroughly to check whether it’s mature for manufacturing. If it matches any of these criteria, it probably isn’t ready yet.

A Vague Idea of the Product

The only idea you have is all in your mind, unfortunately, not any manufacturer works on ideas and hence they might not take you seriously. Manufacturers work on tech packs that include the design, data, bill of materials, instructions, etc. to build prototypes and start mass production.

Rather than keeping the idea in your mind, you need to put the idea on paper and create a functional, mature design with instructions for electronics manufacturing in China. If you’re not a designer, you might need the help of an industrial designer to visualize your ideas and make them functional for electronics prototyping. The process might take weeks or months before you could present it to a manufacturer.

Unclear Understanding of Cost and Competition

A successful product launch isn’t merely about bringing the product to life. You’ll need an in-depth and effective marketing strategy, sales, distribution, and support team in place. On top of that if you fail to understand the cost and competition of the market, for instance, if the market is dominated by established competitors, it’s unlikely that you can compete on price if you’re planning to produce lesser units at the initial launch.

If you fail to understand the cost of manufacturing, logistics, competition, etc, you’ll cut short your chances of success.

Unclear Target Market

Regardless of how good you are at developing products, if you fail to match them with a target audience from the target market, you’ll run out of capital soon as the product fails to attract buyers.

Work on Nothing Else Except the Industrial Design

With 3D printing technology becoming more and more prevalent, it can take as quick as minutes or hours to produce a 3D-printed sample of your product. It could be enough to start an early marketing campaign, electronics crowdfunding campaign, or pitch to investors. However, if you stop at a 3D prototype and work on nothing else, you might be inviting lots of surprises.

Though you can outsource the design and manufacturing to manufacturers or other 3rd party services providers, without your supervising the process the outcome can be non-satisfactory, which tends to lead to quality issues in mass production. Whatever you choose the responsibility of ensuring a functional prototype falls onto you.

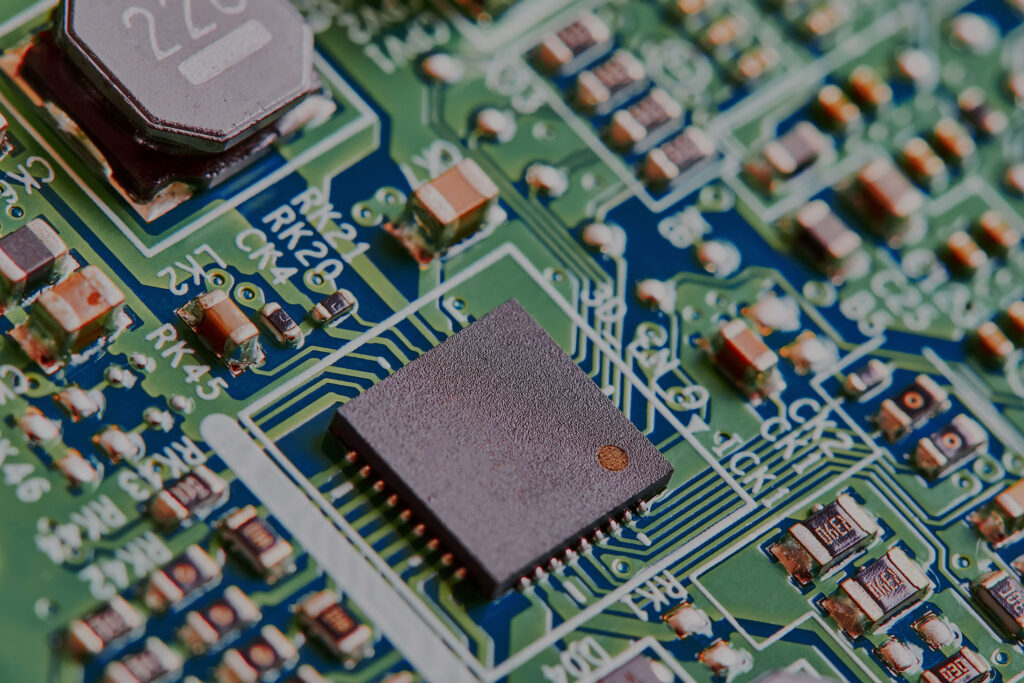

It’s better to involve a dedicated team to work out the circuit, PCB, and prototypes.

If you find your idea falls short of maturity, you’ll have to take critical steps in doing market research, working on the tech packs, creating prototypes, testing the products and the market, and developing effective business strategies.

Working with the right partner will save you tons of time and trouble bringing your product to life. BIS is a leading electronics manufacturing service provider for many established clients.

Talk to our electronics manufacturing experts to know more about getting your products manufacturing-ready.

Leave a Reply