The importance of electronics testing while manufacturing electronics in China can’t be overemphasized. Strategic electronics testing is a process of investigating and testing an electronic to rectify any error before launching it into the market. If you’re taking a nonchalant way in electronics testing, you might risk failing them in the field as an electronic product is often made up of hundreds or even thousands of tiny components.

Table of Contents

Though the prototyping units might work as expected, there is no guarantee that the mass production units have the same perfect performance. The reliability and functionality of an electronic product can be affected by a variety of factors. For instance, the transmit pin of a communication IC isn’t soldered well, which causes intermittent transmission loss. A problem like this is not easy to detect via visual inspection, however, it’s fatal to the proper functioning of the product. Therefore, strategic testing is critical to making your product launch a success.

When Should You Carry Out the Tests?

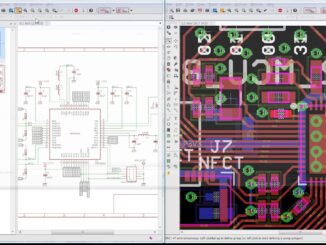

When is the best time to start testing your electronics? Seasoned electronic engineers know well that you can’t wait for the PCB to be fully assembled as most people presume. By then, it’s more complicated to carry out the tests. Even if you identify the actual issue, you have to remove some of the components to fix it. The best time to test your electronics is post-fabrication and post-assembly.

Post Fabrication

It’s critical to have your PCB manufacturer test the PCB upon fabrication to make sure each of the copper connections matches the netlist and get rid of any shot circuits from thin strips of unetched copper. This is usually done by a fixture test or a flying probe test. The former is more cost-effective if you’re fabricating a big quantity.

Post Assembly

With post-fabrication tests, the PCBs seem complete as soon as the components are assembled. However, you shouldn’t just stop here. There’re some extra tests that need to be done before they’re ready to be powered on. Often automatic optical inspection tests should be done on every piece of the assembled electronic product. They would be scanned for anomalies like short circuits, insufficient solder, and dry joints using an optical inspection machine.

How to Test Your Electronics?

While you can leave post-fabrication and post-assembly tests to machine, for other tests such as functionality and burn-in tests you’ll have to take charge.

Functionality Test

With the previous tests now you’re sure that the PCBs are error-free. However, you have to make sure if there are any other issues with the components you outsourced from a third-party component supplier. There is often a defective rate and there’s a chance that a few of them might have issues. You don’t want bad reviews from frustrated customers that might ruin the reputation of your brand. As a result, it’s critical to run a functionality test on every piece to make sure they’re functioning properly according to the specifications. You’ll have to set up preconditions for the tests and the expected results for each functionality.

Burn-In Test

Even if you’re sure the PCBs function perfectly, don’t rush to send them to the customers. There’s another final test that can give you the confidence to make sure the product is unlikely to fail within a short period of time. It’s common with electronics that they might materialize after using for a period of time. That’s where the burn-in test steps up to help. It might not sound practical to test the PCBs indefinitely, it certainly helps to power up the PCBs and let them run for 24 hours.

What Should You Be Aware of in Electronics Testing?

The following are some common modules that you should pay special attention to ensure they perform well in the field.

Power Delivery Network

A power delivery network is inbuilt in every electronics product. When testing the power delivery network, you must make sure the operating voltage on the supply traces is at their respective value. If your electronic products contain power-consuming components such as bright LEDs, you should make sure that the voltage reading remains consistent even when the product is running at its maximum power.

Microcontroller

The microcontroller is the centrepiece of the circuit, especially in an embedded system. It plays a decisive role in the proper functionality of the product. It’s recommended to have a test firmware that allows the electronic engineers to test out the I/Os, memory, communications, and other peripherals to make sure they’re functioning properly. In addition, it’s critical to make sure the microcontroller is oscillating at the right frequency, otherwise, it might disrupt the timers and code executions of the microcontroller.

I/O Modules

The I/O modules on the PCBs might be in different forms, for instance, signal relays, optocouplers, and multiplexer ICs. Regardless of how the I/O modules are built, you should test each of them to ensure proper functionality.

Electronics testing is a tedious and complicated process that might significantly increase the cost of the product if the design is complex. You need to develop a strategic product testing approach with step-by-step instructions on how the tests should be carried out. If you’re producing thousands or tens of thousands of pieces, it’s more efficient to develop an automated testing jig to run the tests with minimum human intervention.

Leave a Reply